WELD CLEANOX S-DIGIT

WELD CLEANOX S-DIGIT electrochemical system with digital adjustment of functions and equipped with an intuitive multilingual display

This innovative electrochemical system allows to carry out the classic processes

DEGREASING, PICKLING, ELECTRO-POLISHING, PASSIVATION and ELECTROCHEMICAL MARKING.

with the possibility of being able to carry out the treatments e

work with TWO OPERATORS at the same time.

The control panel of our electrochemical system changes as in the slideshow next, it has 13 functions.

Each time the (MODE) button is pressed, the device changes operating mode.

WELD CLEANOX S-DIGIT is the ideal solution for the instant ecological cleaning of welds and large stainless steel surfaces.

On stainless steel for any type of finish, optimizing times and safety for the operator.

The advanced technology of WELD CLEANOX S-DIGIT through the appropriate output and the great power of its inverter, equipped with inserts from 10cm to 30cm, also

allows the treatment of large surfaces, such as, for example, the silos of the agri-food or wine industry .

The degreasing, pickling, passivation and polishing processes obtained with WELD CLEANOX S-DIGIT require the use of particular electrolytic solutions.

Use only WE KEM solutions, choosing the most suitable product based on the process to be carried out:

- WE DEK ELT GP (light), suitable for the pickling of welds;

- WE DEK ELT R (strong), suitable for a more efficient pickling of welds, but also for polishing them;

- WE CLEAN ELT, suitable for degreasing welds or part of the products;

- WE PASS ELT, suitable for the passivation of welds or part of the products;

- WE GLOSS SE, optimized product for welding polishing;

- WE MARK ELT, electrolytic solution for a darker and more evident marking.

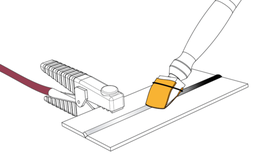

Electro-pickling with pad and carbon fiber brush

Benefits and Tips

- The larger pads are particularly suitable for treating surfaces where the welds are wide and linear.

- Brushes, on the other hand, are useful for treating hard-to-reach welds (corners / gaps).

Electro-marking or electrochemical marking

The WELD CLEANOX S-DIGIT device can be used not only for cleaning (pickling) and polishing welds, but also for electrochemical marking of stainless

steel.

This function exploits the principle of electrolysis by means of neutral liquids which are neither irritating nor corrosive.

It is possible to instantly imprint any logo on the stainless steel (using a customized screen) and obtain both a darker and

more evident marking and a lighter marking.

Silk-screen marking

Thanks to their resistance to corrosion and speed, screen printing screens are the ideal solution for making large logos and brands even on thin thicknesses

without risking deformations.

The high stability of the markings and the total absence of solvents, acids and hazardous substances allows the use of electrochemical marking even in the food,

medical and pharmaceutical sectors.

Use only original marking kits and screens. Non-certified products, such as unsuitable electrolytic solutions or marking inserts and felts not specifically designed

for this function, could cause permanent damage to both the device and the workpiece.

To purchase customized marking kits and screen printing screens, please contact us: WE KEM SNC (info@wekem.it).